Whittier Local Delivery, Set-Up and Take-Away

Old Mattress

BEFORE YOU BUY a Natural Mattress in the Long

Beach area, compare

price, quality, guarantee and service . . . Then talk to the people who

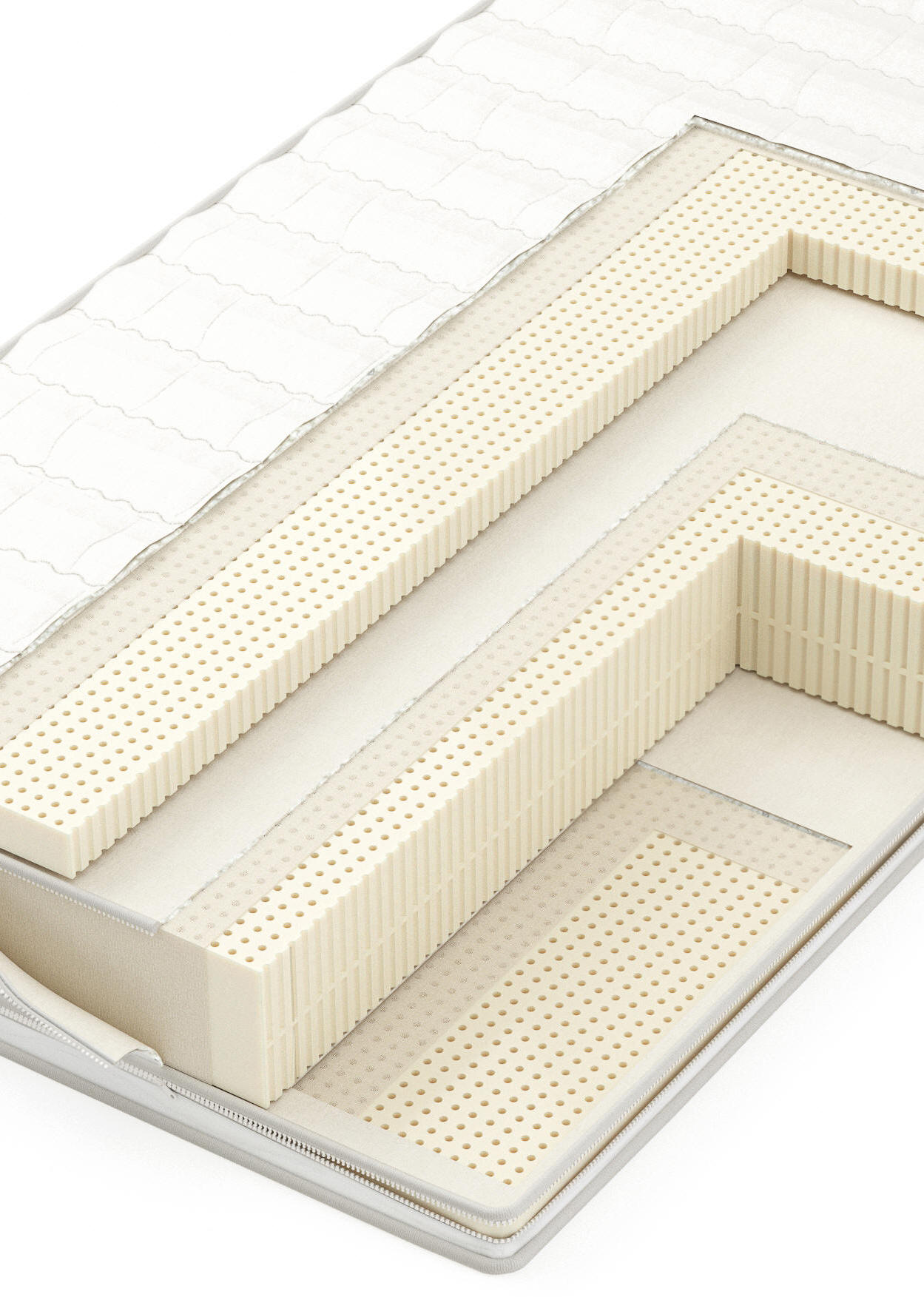

make AMERICA'S BEST-BUILT LATEX MATTRESSES. Our Natural Mattresses

are hand-made one at a time, completely reversible, quilted on both

sides, handles and a zipper, and have a 20-year limited warranty.

We have 3 different Natural Mattress Models; each in (4) four different

firmnesses: Soft, Regular Firm, Extra Firm and Ultra Firm.

|

%20(2)%20(1).png)

.jpg)

%20(2).jpg)

.jpg)

.jpg)

%20(1).jpg)

.jpg)

%20(1).jpg)

.jpg)